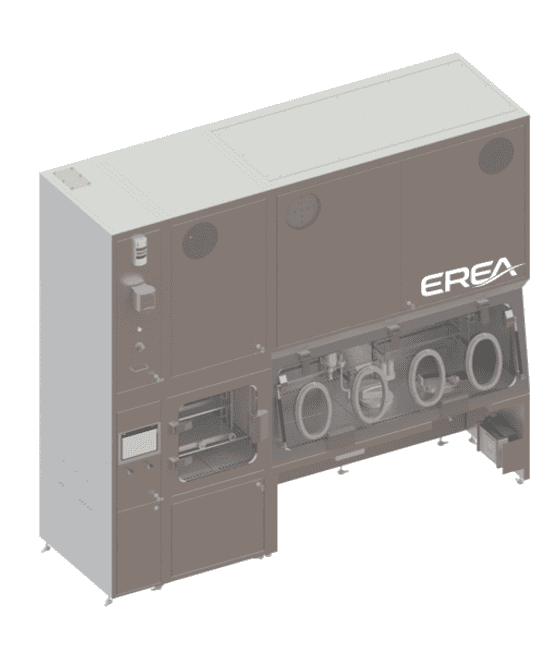

Pharmaceutical Isolator Qualification

EREA is a committed company that provides high quality pharmaceutical equipment that meets current standards and regulations.

Equipment qualification is an essential step in ensuring that an installation is reliable. It is therefore an essential technical service to ensure that the classification of equipment and installations is maintained. EREA installs containment systems and ensures their commissioning and qualification.

Customised Technical Solution

Static and Dynamic Protection

Rapid Installation and Implementation

Easy-to-clean Surface

Would you like an estimate for your project?

Don't hesitate to contact us for a personalised quote.

They Trust Us

FAT/SAT: an Important Technical Service

EREA provides FAT (factory acceptance test) /SAT (site acceptance test) services for each insulator order. These are essential steps that verify the conformity of the design and documentation of the material. FAT checks precede the IQ (installation qualification)/QO (operational qualification) tests and qualifications performed before production launch.

Factory Acceptance Test: Equipment Qualification According to Defined Protocols

Factory FAT protocols are performed at the equipment manufacturer’s facility according to the equipment design. They ensure that the system and its components function properly. These protocols certify the manufacture of the equipment, its compliance with current standards, and its performance. Finally, these controls are used to analyze the equipment’s technical documentation to examine its consistency with the installed components.

Site Acceptance Test or SAT

These are tests at the customer site. They take place after the final configuration and the complete installation of the equipment on its future production site. These tests must show that the machine is properly installed through a series of checks, tests and IQ/OQ qualifications.

Ensuring that Plant and Equipment Slassification is Maintained

At EREA, FAT/SAT checks ensure that equipment and facilities are classified according to test methods that comply with standards (ISO 14644). Among other things, EREA performs measurements of air speed and flow, temperature, differential pressure and humidity, particle counts and filter integrity tests, and recorded smoke tests to demonstrate the homogeneity of the flow and the absence of turbulence.

Why Choose EREA?

Equipment qualification according to strict and standardized protocols is an essential step. EREA puts this expertise at your service. As a specialist in containment systems, we offer you customized solutions that will fit in your units and meet your needs. We define our products in full compliance with the pharmaceutical regulations in force thanks to the FAT/SAT controls that we provide.

As a human-sized company, we are at your service to answer all your questions.

Need a specific configuration? Customised dimensions?

Discover our insulators, tailor-made to meet your requirements.