Isolators for Aseptic-Toxic Processes

Overview

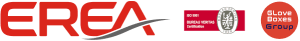

Photos

Isolators for Aseptic-Toxic Processes

Provides strict protection for the operator, the environment and the product when handling toxic or cytotoxic products.

- Powder sampling and formulation

- Tightness class: 1 or 2

- Flow equipment: unidirectional (laminar) vertical

- Regulation: temperature, pressure, excess pressure, humidity

Customised Technical Solution

Static and Dynamic Protection

Quick Installation and Implementation

Easy-to-clean Surface

Features

- Cleanliness class: A class (Iso 5)

- Tightness class 2 or 1

- Turbulent flow equipment

- Continuous regulation of negative pressure to -75 Pa to compensate for filter clogging,

- Operator safety in the event of glove tearing (flow speed of 0.5 m/s guaranteed at the centre of the glove ring),

- Underpressure containment via open-loop filtered ventilation,

- Tightness: class 2 (ISO 10648-2 standard) / class 1 optional,

- Secure filter replacement (BIBO),

- Ventilated airlock with interlocking doors.

Options

- Integration of various equipment: RTP port with continuous liner/Beta Bag, containment valve, grinder, scale, robot, air and water shower, CIP/SIP with diamond-shaped bottom to facilitate drainage of liquids,

- Double inlet/outlet filtration,

- Environmental monitoring and control: oxygen, humidity and temperature control,

- Electrically adjustable worktop height,

- Customised interior fittings,

- Static electricity reduction,

- SMEPAC testing.

Custom-Made Design

Regulation:

- Temperature

- Pressure

- Vacuum

- Humidity

Filtration (HEPA):

- Double filtration at supply

- Double filtration on return ;

- BIBO filtration on return ;

- Open loop ventilation

- Dynamic and static containment

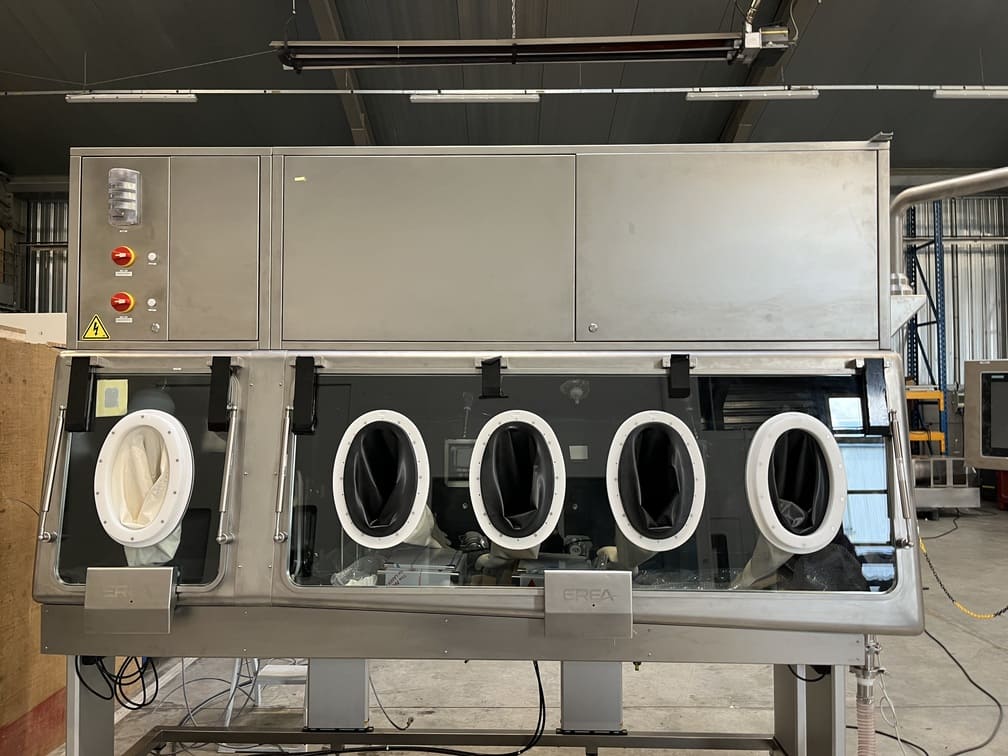

- Materials: 100% stainless steel

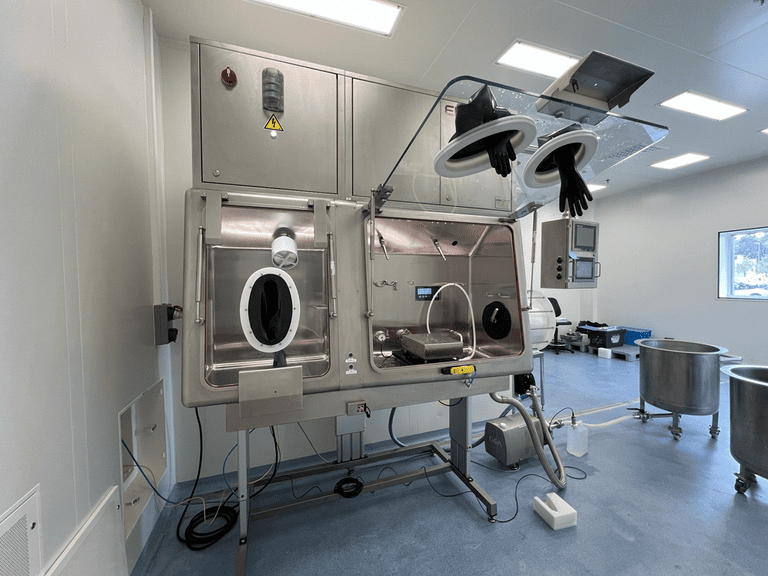

- Touch screen: HMI on rotating arm

- Dimmable LED lighting

- Can be 100% customised and dismantled

- Audit Trail

Product Modulation

- Automatic opening and closing of doors for optimum ergonomics,

- Unidirectional laminar flow or turbulent flow under negative pressure,

- Several door opening options between airlock and chamber,

- 100% 316L stainless steel construction,

- Easy and safe glove change,

- Filter clogging control,

- Rapid transfer ports (RTP),

- Rounded corners (30 mm radius),

- Glove integrity tester,

- Securit glass panels,

- Robotic integration,

- Touch screen.

EREA has designed aseptic-toxic process isolators to ensure consistency in an industrial process where protection of product, personnel and the environment is essential.

This isolator ensures safe and reliable production as required by the pharmaceutical industry and related applications.

Our Isolators For Aseptic-Toxic Processes

EREA has developed a range of isolators for aseptic-toxic processes. Watertight and hermetic, the isolator consists of a perfectly sterile main space where you can handle toxic pharmaceutical or biotechnological products. With turbulent or laminar flow, our isolator can reconcile sterility and toxicity (EPO 5 with a vacuum up to -80 Pa) with temperature, pressure and humidity regulation. It also integrates transfer systems that enable the entry and exit of products and the elimination of waste while respecting containment and aseptic conditions.

Equipped with high efficiency particulate air (HEPA) filters, the isolator also uses an integrated bio-decontamination system (by H2O2). These technologies are designed to eliminate microbes and particles from all possible sources of contamination.

EREA isolators comply with all current standards and can be customised to suit your industrial needs.

EREA, Manufacturer of Customised Isolators

Innovative products, customised solutions and efficient service and support have made EREA a major partner for the pharmaceutical industry. Our aseptic-toxic process isolator meets the requirements of pharmaceutical production by integrating innovation and technological know-how.

From design to commissioning, EREA takes care of everything. We provide personalised advice to deliver customised isolators. We have also developed a range of turnkey iso-technical solutions: PSM, sampling cabin, RABS, transfer trolleys, weighing station. All our solutions are adapted to the new realities of the pharmaceutical industry.

EREA Pharma, at your Service to Meet your Needs

For over 30 years EREA has developed feasible adaptations, processes and sterile tests for the pharmaceutical industry. Our equipment benefits from the latest technological innovations, our equipment is manufactured in France and complies with all current standards.

In order to provide you with tailor-made iso-technical solutions, EREA has a 2,500 m2 workshop, a highly specialised team, airflow simulation and 3D visualisation software. We have also set up a clean room to carry out full-scale ergonomic tests.

Get information about our equipment by contacting our technical teams. We can provide you with fast, detailed and personalised answers.

Need a specific configuration? Customised dimensions?

Discover our insulators, tailor-made to meet your requirements.