Pharmaceutical ampoule / glass vial filling line

A pharmaceutical ampoule filling line ensures the precision, sterility and repeatability required for modern production of injectable medicines. To understand the technical requirements associated with this type of equipment, it is essential to first examine the container itself: the pharmaceutical ampoule.

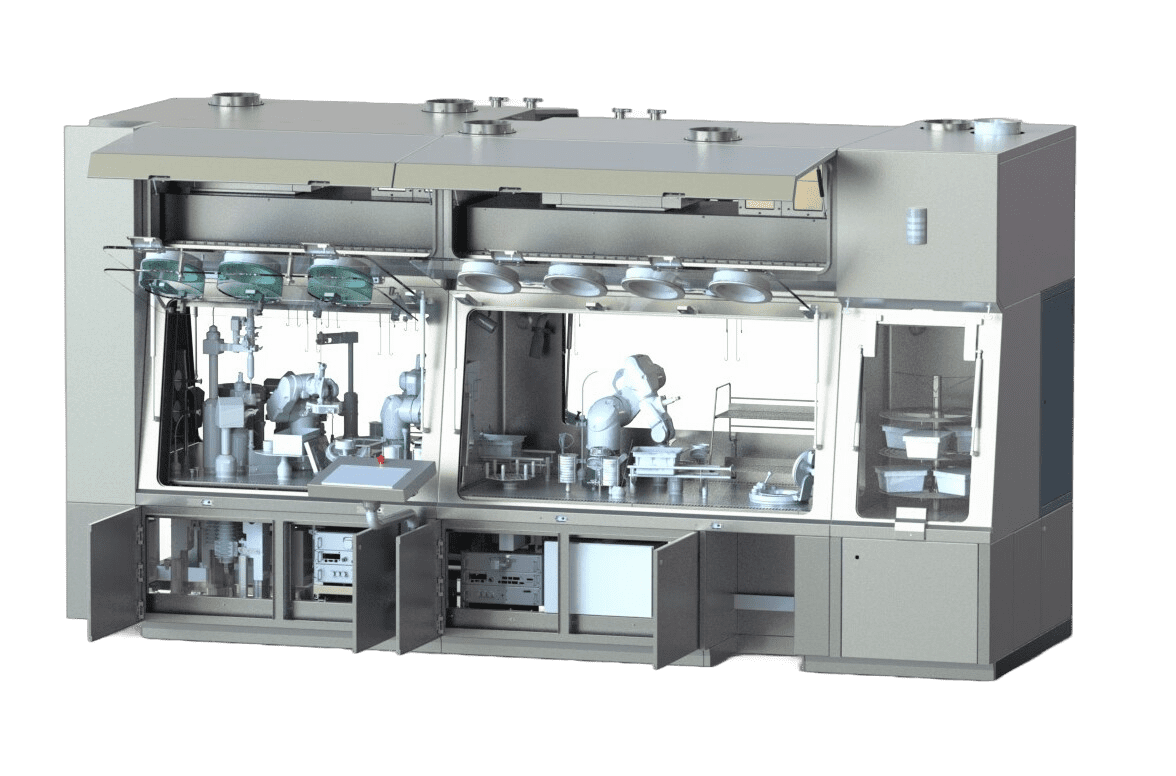

Customised Technical Solution

Static and Dynamic Protection

Rapid Installation and Implementation

Easy-to-clean Surface

Would you like an estimate for your project?

Don't hesitate to contact us for a personalised quote.

They Trust Us

Pharmaceutical ampoules: formats, materials and container characteristics

Glass ampoules are the industry standard for sensitive injectable solutions. Two main categories exist, each suited to specific uses and constraints.

Pulled-neck ampoule

- Material: Type I glass (borosilicate)

- Typical volumes: 1–20 mL

- Closure: Fusion-sealed, opened by scoring/breaking

- Use: Single sterile dose for IV/IM/SC injectables

- Typical products: Anesthetics, solvents, vitamins

- Advantages: Excellent protective barrier, lower cost

- Limitations: Possible generation of micro-glass particles during opening

Snap-off ampoule

- Material: Type I glass

- Typical volumes: 1–10 mL

- Closure: Predefined breaking ring for easier opening

- Use: Single-dose sterile injectables

- Typical products: Antibiotics, analgesics

- Advantages: Easier and more ergonomic opening

- Limitations: Reduced but still present risk of cuts

These formats require a pharmaceutical ampoule filling line capable of precisely handling fine geometries, fragile glass, and sealing operations that demand rigorous thermal control.

Applications and sectors using ampoules

Ampoules are widely used in the pharmaceutical industry for their ability to protect formulations sensitive to oxygen, microbial contamination, or interactions with the packaging. They are used for:

- IV, IM and SC injectables

- Anesthetic solutions

- Antibiotics, analgesics and vitamins

- Solvents, diluents and temperature-sensitive drugs

Their unit-dose format ensures impeccable sterility and optimal traceability, suitable for both large-scale industrial production and specialized small batches.

Pharmaceutical ampoule filling line: erea pharma’s aseptic solution

The aseptic automatic filling machine developed by EREA Pharma is designed to offer full compatibility with both ampoule types. This pharmaceutical ampoule filling line stands out thanks to:

- Precise and repeatable dosing, even with very small volumes

- Reliable handling of fragile glass formats

- Controlled fusion-sealing to guarantee tightness and sterility

- Easy integration into sterile environments or isolators

- Significant reduction in particle and contamination risks

Thanks to its robust and flexible architecture, it meets the high requirements of injectable drug manufacturers.

For more technical information or to request a customized quotation, you can contact our specialist teams — we will assist you in selecting the line best suited to your needs.

Need a specific configuration? Customised dimensions?

Discover our insulators, tailor-made to meet your requirements.