In the process of obtaining ISO 9001 certification, parts of our equipments are identified, marked, controlled, and then systematically released.

All these parts are controlled by our production teams and monitored by our Quality and EHS manager Rémy Rembert, at precise moments in the manufacturing process and with specific quality requirements at each stage.

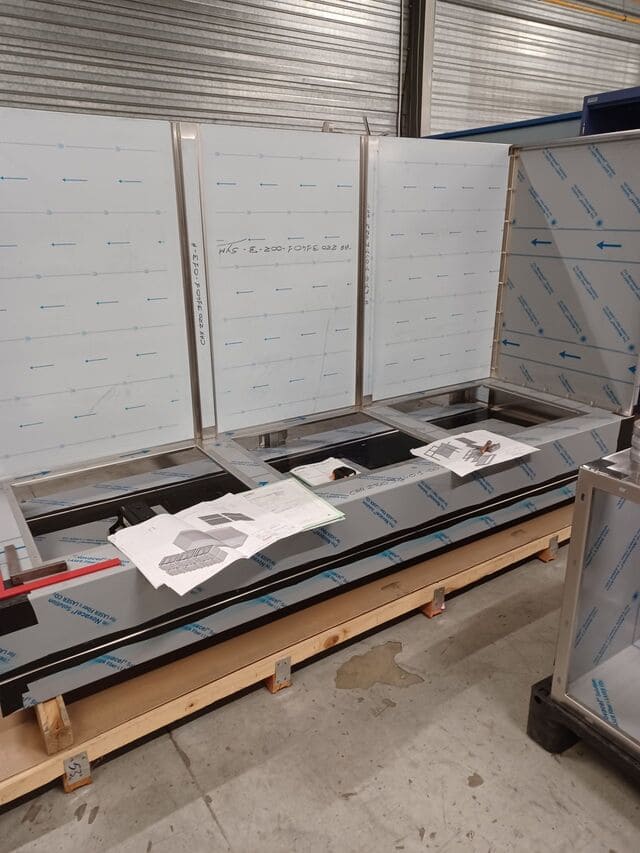

Here, at the sheet metal level, we check the roughness, the welds, the dimensions in relation to the drawing, and the documentation associated with each part. These parts will then be sent to the equipment area after validation of these controls and release of the parts.

Ex : picture 5 : validated part ready for assembly

Another type of quality control will then be carried out according to precise requirements in relation to the components used for the assembly: mechanical, electrical, pneumatic and automatic.

These quality control steps are to be dissociated from the controls carried out on the machine after the assembly of the equipment and that we call FAT.