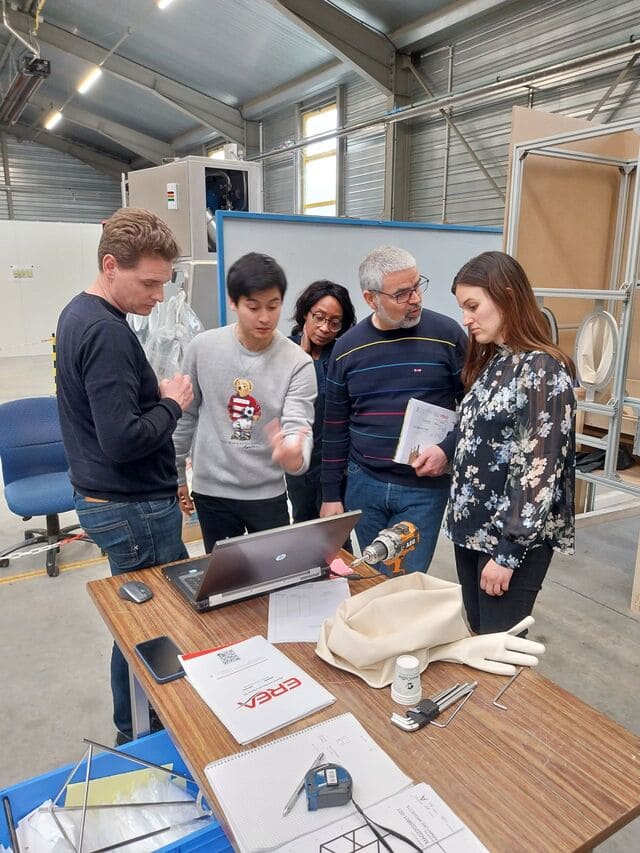

Here’s how, in our company, the validation of a model of RABS is done.

After the manufacturing of the entire line in a wood version, comes the installation of the important elements to be validated for ergonomics, namely the round gloves, the access hatches for setting up a Petri dish or the evacuation hatches. . Everything is provided as adjustable so as to refine the different positions for the users.

Then our customers come to validate the line with their own tools. Users are part of the group for the validation.

After that , and that’s what’s going on, comes the different corrections before the manufacturing of the real thing.

That’s what we call a tailor-made support of our customers from our team.