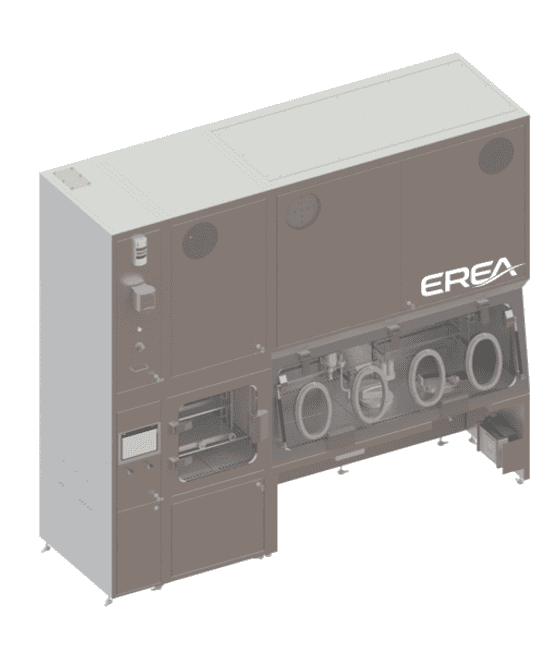

Isolator with Electropolished Finish

In the pharmaceutical field, the isolator, commonly called “glove box”, is an essential piece of equipment for technical manipulations. EREA’s know-how is complete, from the design to the commissioning of these glove boxes.

The finishing stage is essential and allows us to eliminate all imperfections on the surface of the finished products. Among the surface smoothing techniques, two processes are frequently used: electropolishing and bead blasting.

Customised Technical Solution

Static and Dynamic Protection

Rapid Installation and Implementation

Easy-to-clean Surface

Would you like an estimate for your project?

Don't hesitate to contact us for a personalised quote.

They Trust Us

Electropolishing or Bead Blasting?

Among the surface treatment processes, electropolishing and bead blasting are used to eliminate surface imperfections during the finishing process. During their manufacture or machining, parts can be covered with fluids. It is therefore important to remove these impurities from the parts to ensure optimal cleanliness. In addition, smoothing and deburring of the surface is essential at the end of the process, removing roughness and scratches. The result is an aesthetically pleasing part with an even, shiny, satin-finished surface.

Finishing by Electropolishing

Electropolishing is a polishing and deburring technique that uses an electric current to erode metal ions from the parts. The process is based on the principle of electrolysis and involves the flow of a current through an electrolyte, most often a solution of sulfuric acid and phosphoric acid. When immersed in an electrolytic bath, the asperities are eroded. When these microporosities are removed, the metal has a level and shiny surface.

Bead Blasting Finish

Bead blasting is an impact surface treatment process. It consists of projecting beads (often glass but sometimes ceramic) onto a surface. The objective of this process is to strip the part without damaging it. Thus sanded, the surface is satin and shiny.

The waterproof stain remover can be sprayed after the treatment. It avoids the incrustation of indelible marks, and also facilitates maintenance. Finally, thanks to this technique, the mechanical qualities and the resistance to corrosion are improved.

Finishing, an Essential Step in the Manufacture of Parts

Whether by bead blasting or electropolishing, the finishing stage is essential. The objective is to increase the cleanability of the work volume and to optimize the decontamination of the surface. Polishing will give the part a smooth finish by reducing the roughness of the part. This aspect is unlikely to promote the retention of contaminants and will facilitate a more effective cleaning.

EREA: Microblasting of High Quality Steel

EREA has chosen to use the bead blasting technique for the finishing of its various insulator models in order to guarantee impeccable quality.

EREA offers a complete range of insulators and our know-how accompanies you throughout the process: from design to commissioning. We install these containment systems worldwide and ensure their qualification. EREA develops integrated solutions and we adapt to your needs. Do not hesitate to contact us, we are there for you.

Need a specific configuration? Customised dimensions?

Discover our insulators, tailor-made to meet your requirements.