Company

EREA offers a complete range of isolators, laminar flow systems, safety cabinets, weighing stations, transfer trolleys, LAF (Laminar Air Flow) and, in general, all equipment requiring ultra-clean air conditioning, mainly for the pharmaceutical and biopharmaceutical industries.

We define our products in full compliance with current pharmaceutical regulations, and we deploy a strategy based on proximity and customer service. We offer our customers a high level of Know-how in sterile and/or toxic environments and can provide tailor-made solutions to fit in with your units and meet your needs.

EREA installs and qualifies containment systems worldwide. We take particular care to develop integrated solutions aimed at offering our customers the most appropriate solutions that best meet the needs of users.

We use 3D virtual immersion simulation tools to study the ergonomic and aeraulic aspects of each of our installations.

Quality, Compliance and Customer Satisfaction

At EREA, we are committed to providing products and services of the highest quality, in full compliance with the most stringent pharmaceutical regulations. Our customer-focused approach means that we listen carefully to your needs and respond quickly.

Know-how, Innovation and Customised Solutions

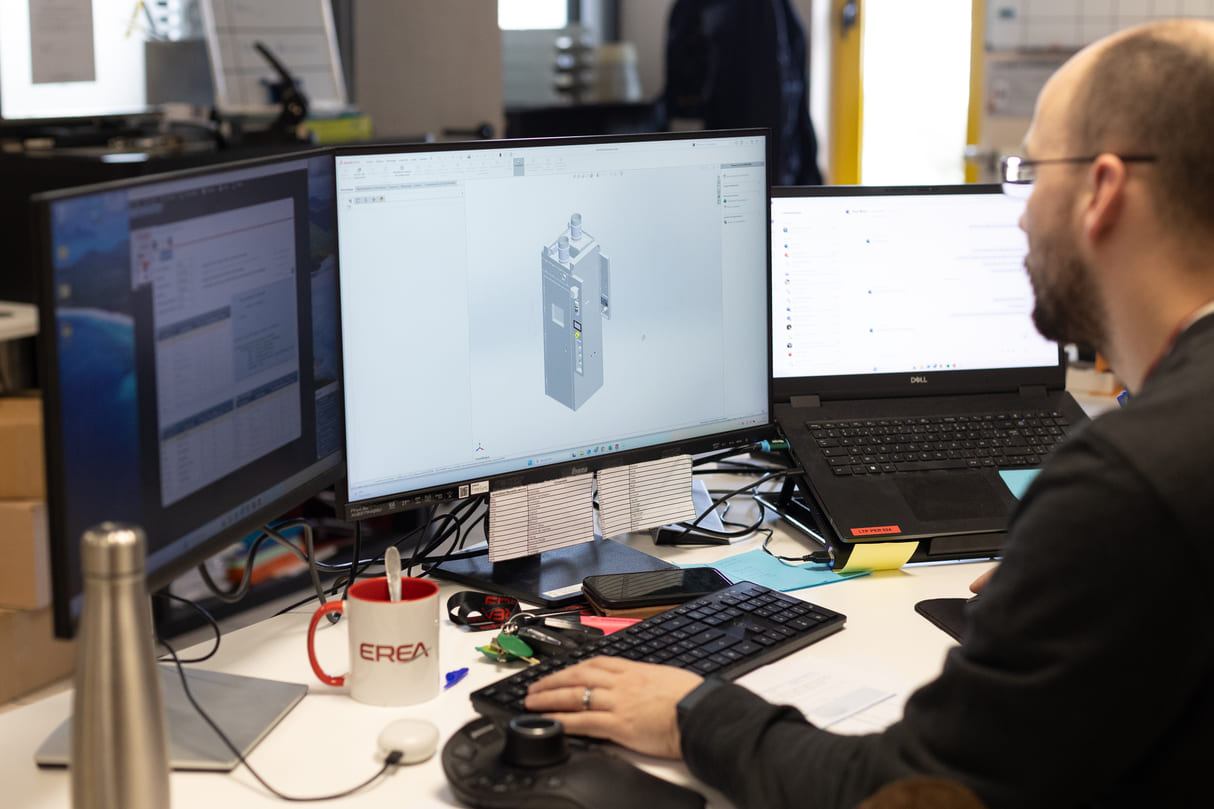

Thanks to our solid Know-how in sterile and/or toxic environments, we can offer you customized solutions that are perfectly adapted to your specific requirements. Our mastery of 3D virtual immersion simulation tools enables us to optimize the ergonomics and aeraulics of our installations, guaranteeing maximum performance and safety.

A Worldwide Service

EREA deploys its expertise across borders to meet the requirements of its customers, wherever they may be. Thanks to an agile organisation and highly qualified technical teams, the company can install, commission and qualify its containment systems anywhere in the world. This ability to operate internationally guarantees customers continuity of service, local support and compliance with local and international standards. EREA is committed to providing a turnkey solution that is reliable and compliant, wherever the project is located.

Our History

A Modern Workshop

Our production site covers 2,500 m² of modern workshops, equipped with the latest technology. Our team of highly-qualified experts is fully conversant with all the issues involved in containment, and is supported by cutting-edge aeraulic simulation and 3D visualisation software.

Putting people at the heart of the EREA approach

People First

We place people at the centre of our concerns. Every employee, customer and partner is regarded as a unique individual, whose needs and aspirations are taken into account.

Fun

We believe that fun at work is a driver of performance. We encourage a friendly, stimulating environment where humour and good humour are welcome.

Teamwork

Collaboration is essential to our success. We encourage team spirit, knowledge-sharing and mutual support, so we can rise to the challenges together.

Empathy

We listen to our customers and employees, and strive to understand their needs and expectations. We cultivate a culture of caring and respect, where everyone feels valued and supported.

Excellence

We are driven by a passion for excellence. We are committed to providing products and services of the highest quality, based on our Know-how.

Intégriy

We act with honesty, transparency and ethics. We honour our commitments and strive to build lasting relationships of trust with our customers and partners.