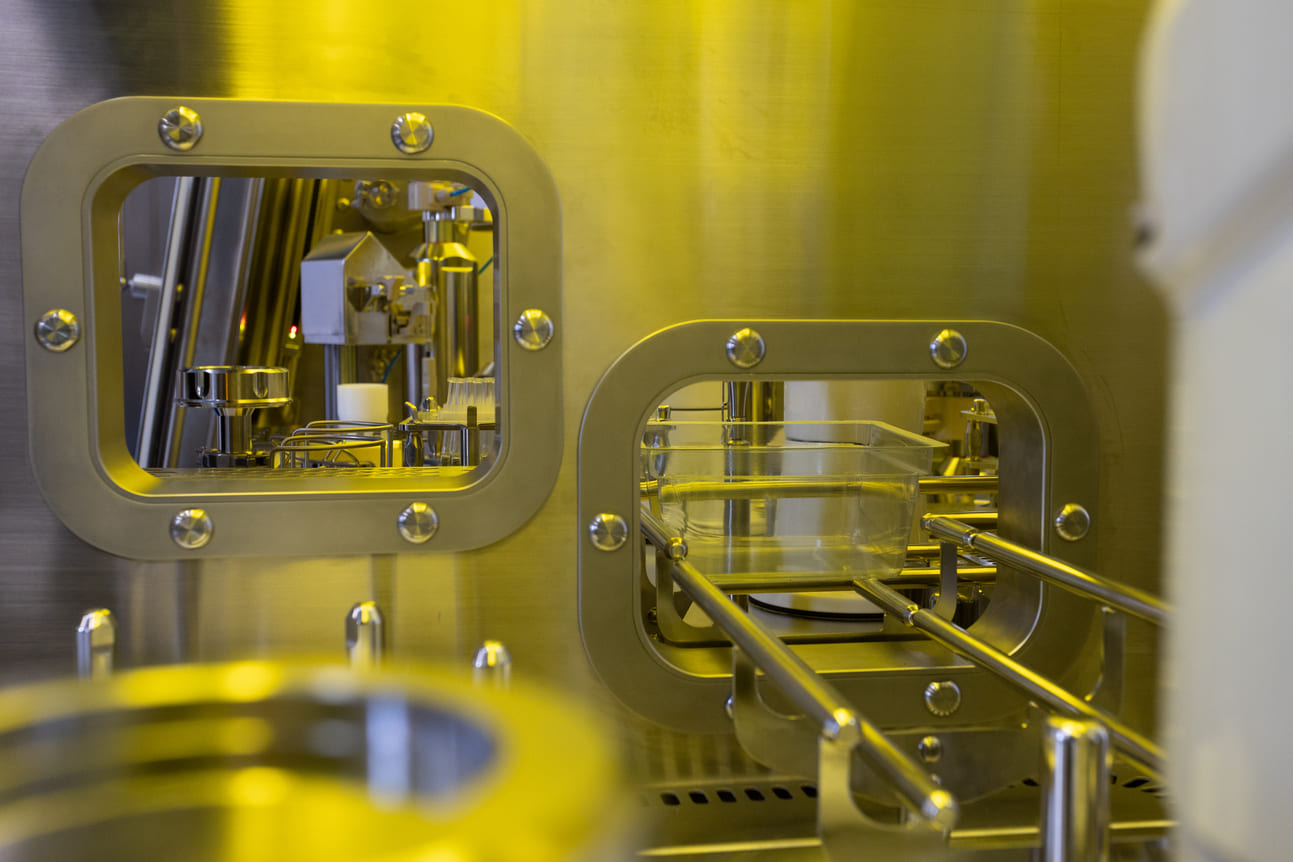

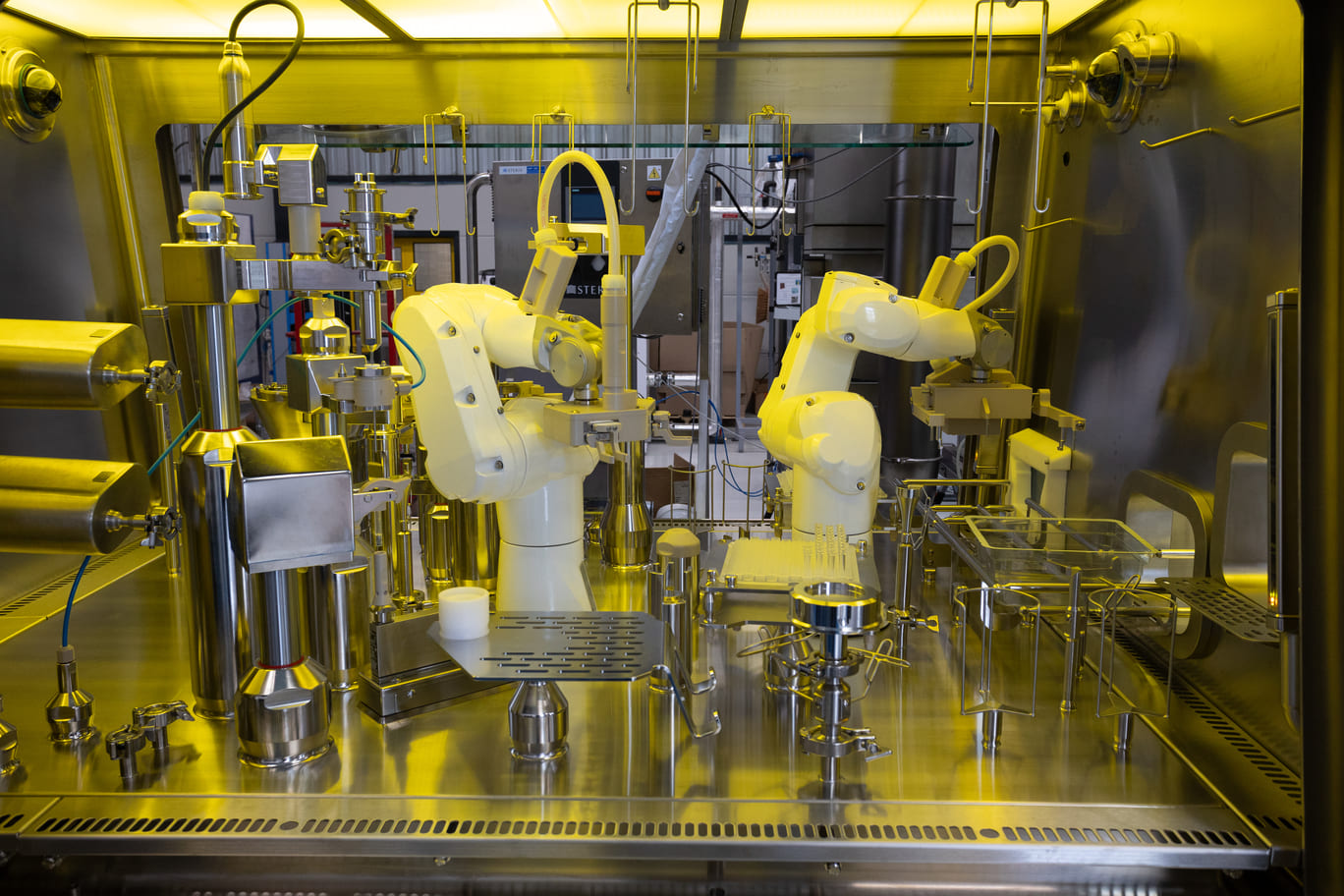

Robotic Line for Aseptic Distribution in Vials and Syringes under Isolator

Overview

Photos

Robotic Line for Aseptic Distribution in Vials and Syringes Under Isolator

- NESTS, vials, syringes, etc.

- Cleanliness class: A class (Iso 5)

- Tightness class: 3 or 2

- Flow equipment: unidirectional (laminar) vertical

- Regulation: temperature, pressure, excess pressure, humidity

Customised Technical Solution

Static and Dynamic Protection

Quick Installation and Implementation

Easy-to-clean Surface

Features

Isolator:

- Air intake through a double pane of glass to save space on the worktop. The panes can be separated for optimum cleaning

- Fast, effective bio-decontamination systems with our partners: STERIS and SOLIDFOG.

Filling Station:

- Different filling systems depending on the liquids, accuracy required and viscosity (peristaltic pump, piston pump, other…), accuracy and repeatability target: < 1%.

- 100% volume control by weighing (IPC 100%), automated discharge

- Can be filled under vacuum or neutral gas.

Compatibility

Compatibility with all Supplier Formats:

- Vials and syringes (BD, SCHOTT, SG-EZ Fill, others…),

- Nest, tray, bulk, etc…

- All types of caps (Stoppers, RayDyLyo® , others…).

Tailor-made Design

- Adaptation of the equipment to the configuration of your venue

- 1/1 scale layout and full project management

- Flexible positioning of your integrated equipment,

- Know-how, advice and proposals.

Aseptic production is an essential pillar of the pharmaceutical industry. It ensures that the various medical products are free from pathogenic contaminants. The automatic aseptic filling line plays a key role in this process. In fact, it enables pharmaceutical liquids to be filled accurately and sterilely. This sophisticated system, which combines advanced technology and automation, offers efficient and reliable solutions to meet industry standards. Here’s what you need to know about it.

How an automatic aseptic filling line works and its features

An automatic aseptic filling line is designed to fill containers with liquid products under sterile conditions, thereby eliminating any risk of contamination. The process begins with the preparation and sterilisation of the containers and closures, often by autoclave or a combination of steam and chemical sterilisation. The sterile containers are then transported to an aseptic area inside the isolator, where they are filled with the liquid pharmaceutical product.

Filling is usually carried out using precise dosing systems, such as peristaltic pumps or volumetric dosers, which ensure accurate and repeatable filling. Integrated sensors and vision systems monitor quality at every stage to detect and rule out any anomalies. Once filled, the containers are sealed under aseptic conditions. Finally, they undergo rigorous quality testing.

Advantages of using automatic aseptic filling lines

One of the advantages of using an automatic aseptic filling line is that it reduces the risk of contamination. More specifically, by automating the filling and sealing process in a controlled environment, it minimises human intervention, which is a potential source of contamination. This ensures that filled products remain sterile and safe for patients. Accuracy and repeatability are also key benefits.

In fact, automated dosing systems ensure that each container receives exactly the amount of product required. This reduces waste and ensures compliance with dosing specifications. This is particularly important for medicines, where variations in dosage can have a significant impact on efficacy and safety. Automatic aseptic filling lines also improve production efficiency.

These systems can operate continuously, increasing throughput and reducing downtime. What’s more, integrated monitoring systems enable problems to be detected quickly. Last but not least, there is a high degree of flexibility. In other words, these lines can be configured to handle a wide variety of containers and volumes, adapting to the specific needs of different products and projects.

EREA Pharma: a specialist in automatic aseptic filling lines

EREA Pharma is a leading developer and supplier of automatic aseptic filling lines. Our technical expertise and commitment to innovation enable us to provide you with solutions that meet the requirements of the pharmaceutical industry.

We offer aseptic filling systems incorporating the most advanced technologies to guarantee optimum performance in terms of precision, reliability and sterility. Our filling lines are equipped with high-quality components and sophisticated control systems to ensure efficient production and compliance with regulatory standards.

Our company also places great emphasis on customising our solutions, so that you have tailor-made lines perfectly suited to each of your projects. To support you even further, we also provide an after-sales service and technical support. We offer you ongoing assistance to ensure that your aseptic filling lines remain operational and efficient throughout their lifecycle.

In any case, the automatic aseptic filling line is essential to ensure the sterility and safety of the various pharmaceutical products. EREA Pharma is the partner of choice if you are looking to optimise your aseptic filling processes and guarantee the quality of your products.

Would you like to find out more about what we can do for you? Contact us now.

Need a specific configuration? Customised dimensions?

Discover our insulators, tailor-made to meet your requirements.