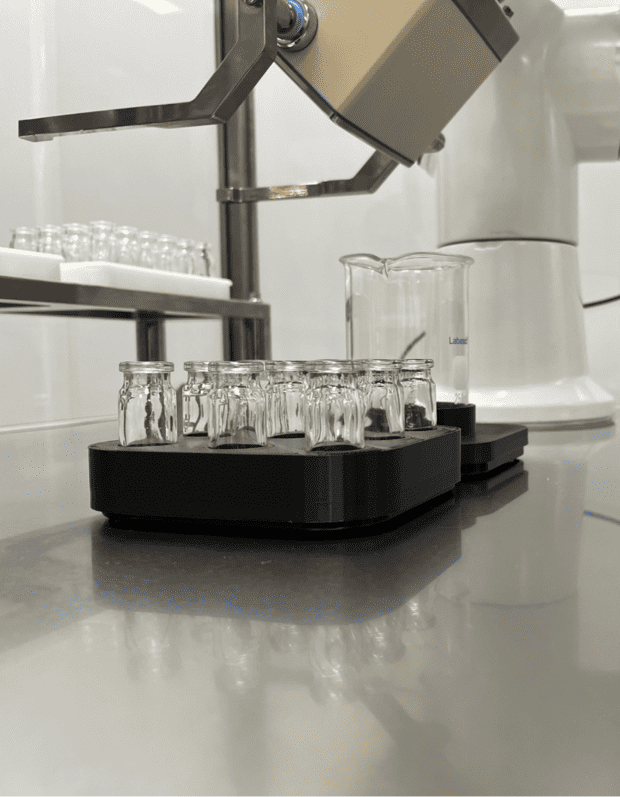

Accopos 6D system (Planar)

The integration of the Acopos 6D system (Planar) into filling lines and isolators represents a major step forward for the pharmaceutical industry. This innovative system is based on magnetic levitation technology, enabling components to be moved precisely and without contact, thereby reducing the risk of contamination and improving the flexibility of production processes.

Technology and Features

Benefits and applications

Documentation

Technology and Features

- Movement in six degrees (translation and rotation) for precise handling of vials and syringes.

- No mechanical contact, reducing wear and the risk of contaminating particles.

- Flexibility and modularity, enabling rapid adaptation to different production configurations.

- Seamless integration into isolators, guaranteeing a sterile and safe environment.

Benefits and applications

The use of the Acopos 6D system in an isolator improves filling efficiency and accuracy, while guaranteeing optimum control of aseptic conditions. This technology paves the way for more flexible, automated production that complies with the most stringent standards in the pharmaceutical sector.

Its integration enables us to meet growing quality and safety requirements, while optimising productivity and minimising the risk of contamination. This makes the system a future-proof solution for filling lines in controlled environments.

Want to find out more about EREA innovations?

Our R&D team plays an essential role in the innovation and development of our industrial solutions.