Glove Integrity Tester for Isolators

Documentation

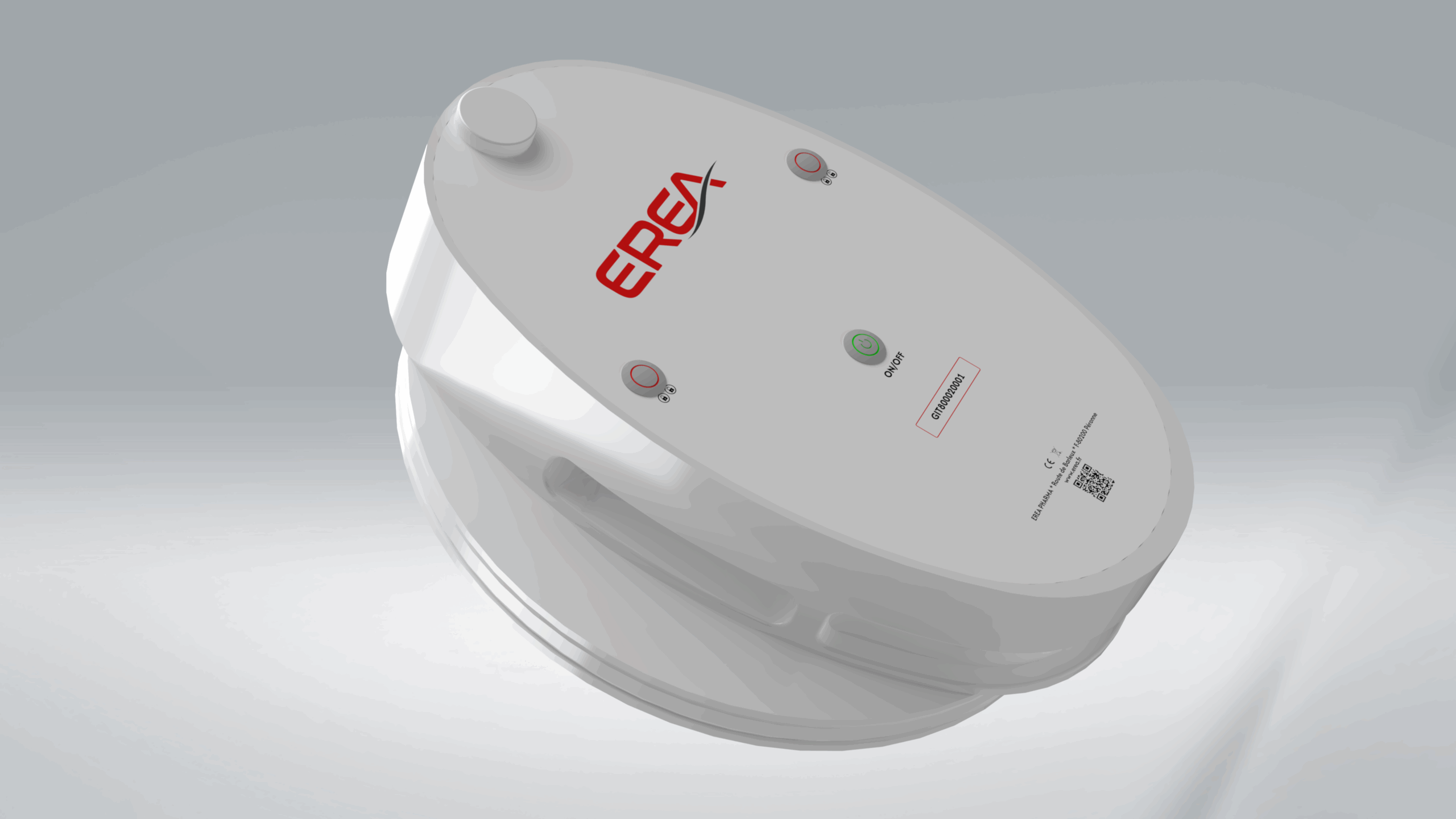

Description of the EREA glove tester

The tester developed by EREA is:

- Equipped with two sensors that detect pressure inside the glove

- Integrated with a Siemens HMI interface for complete control

- Designed to be lighter, with lower power consumption and longer battery life

- Easy to use, with less mechanical complexity

- Adaptable to different glove ring formats (round, oval, etc.)

Exclusive dual sensor technology

The EREA glove tester is controlled via the Siemens WinCC Unified system, a benchmark in the pharmaceutical industry. This interface offers complete and intuitive traceability, with: Automatic report generation, Alarm log available for consultation at any time, Secure audit trail to guarantee data integrity. A solution perfectly suited to demanding and regulated environments. Thanks to its intelligent design, the tester allows constant calibration with pressure sensors without any disassembly. It incorporates exclusive dual sensor technology:

- The first sensor measures and regulates the pressure in the glove,

- while the second continuously monitors the reliability of the first.

If a discrepancy is detected, a preventive alarm is triggered to alert the user to the need for calibration.

The EREA tester is WPA2 Enterprise compatible, a centralised authentication protocol ensuring that only authorised devices can connect to the Wi-Fi network. In addition, our Wi-Fi router is configured to be invisible to computers: it does not broadcast its name (SSID). An ultra-secure connection, only accessible to users with login details – effective protection against cyber attacks.

Operating principle

Thanks to its operating principle based on Hagen-Poiseuille’s law, the tester can simulate leaks equivalent to those generated by very small defects. For example, a calibrated 260 μm orifice used in testing is equivalent, in terms of leak rate, to a hole of around 113 microns in a glove. This means that the tester is sensitive enough to ultimately detect a hole of this size, thus ensuring a high level of micro-leak detection.

Once a year, secure and traceable calibration is carried out using a dedicated programme in the HMI and a test bench that reproduces the test conditions, enabling the accuracy of the pressure sensors to be checked and validated without dismantling, with the option of on-site intervention or return to EREA.

Want to find out more about EREA innovations?

Our R&D team plays an essential role in the innovation and development of our industrial solutions.