Closed RABS – EREA Pharma, Manufacturer of Closed RABS

The Restricted Access Barrier System (RABS) is a barrier solution used to separate the operator from the product.

It separates two zones to contain contaminants. Thanks to this equipment for the pharmaceutical industry, the operator takes no risk when handling hazardous products, thanks to rigid separations. EREA Pharma is a designer and manufacturer of closed RABS.

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

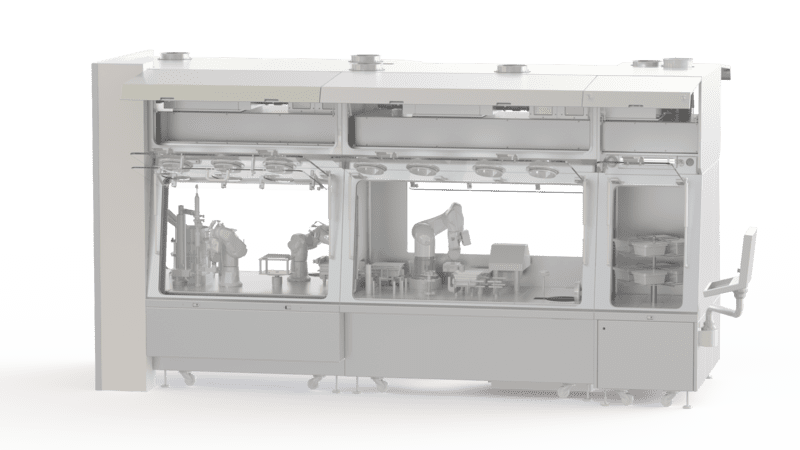

RABS or restricted access barrier systems made in EREA Pharma

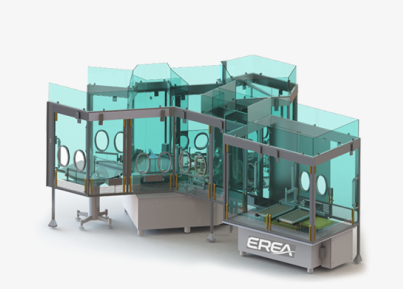

EREA Pharma designs and manufactures restricted access barrier systems. Depending on the requirements of your pharmaceutical processes, you can choose between an active (Open RABS active) or passive RABS and a closed RABS. The two systems are different in that the latter incorporates a closed system, protecting the internal atmosphere from the room environment.

EREA restricted access barrier systems, whatever their model, are designed to meet the needs of the pharmaceutical industry. Thanks to the barrier system with which they are equipped, they effectively protect the operator and the environment during the handling of toxic or hazardous active ingredients. The separation system also protects sterile products from external elements that could contaminate them.

Depending on the requirements of your pharmaceutical processes, EREA Pharma can provide you with customized restricted access barrier systems.

The difference between closed and open RABS

There is a major difference between open and closed RABS.

Open RABS

Open RABS can be divided into open RABS with passive flow and open RABS with active flow.

The open RABS with passive flow is characterized by air supplied from the cleanroom filtration system in which it is installed (customer’s blower ceiling (FLV)). This RABS model is equipped with an air exhaust system at the bottom. It also features high-visibility PETG doors. To guarantee operator and product safety during operation, EREA equips its passive open RABS with interlocking doors. This model is used for handling and processing non-toxic products.

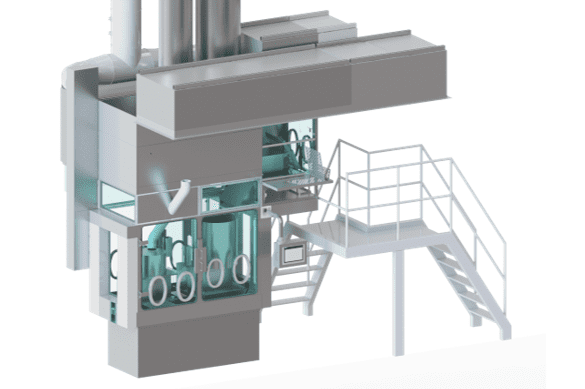

The closed-flow open RABS incorporates a closed system. This means that the RABS enclosure is hermetically sealed. This model has its own air supply and recirculation system. Thanks to its high level of containment, the open RABS with closed flow is designed for handling and processing cytotoxic or highly active products. Thanks to its design, its properties are almost identical to those of an isolator.

Closed RABS

The EREA active-flow closed RABS features a laminar-flow system. It also incorporates filtration/ventilation units. Air quality in the enclosure is guaranteed by a HEPA (High Efficiency Particulate Air) filtration system. EREA’s RABS Fermé also features tempered glass doors for complete closure and safe separation. It is designed for a variety of uses, such as toxic or sterile processes. Depending on your needs, it can be fitted with interlocking access doors, RTP systems or glove ports.

EREA Pharma – Designer and manufacturer of closed RABS

EREA Pharma is a designer and manufacturer of restricted access barrier systems for the pharmaceutical industry. Made in France, this equipment is manufactured in compliance with current standards and regulations. Calling on this manufacturer means that you benefit from unrivalled support from the design of your project right through to the integration of your closed RABS made in France. EREA technicians are on hand to answer all your questions.

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don’t hesitate to contact us for personalised information about our isotechnical products.